The main purpose of a fire door is to prevent the spread of fire and/or smoke when they are shut and to provide a means of escape when open. Internal fire doors are typically made from fire resistant metal, timber or composite materials and are equipped with special hardware to ensure proper closure in the event of a fire.

How our fire rated internal doors stop the spread of fire

Following fire resistance testing in a furnace, the performance is classified for a period of time. Our glazed doors are constructed from materials that will withstand fire for up to 120 minutes.

Internal fire doors are equipped with intumescent strips to the edges of the door or frame. These strips expand when exposed to temperatures that would be generated by a fire (typically in excess of 180°C), filling the space between the door and frame. This, in effect, seals the room and prevents fire from spreading between compartments for a nominated period of time. It is important to remember that fire doors will only perform correctly when shut and should therefore be fitted with an appropriate self-closer

Fire rated internal glass doors help to stop the spread of fire and smoke throughout a building by offering essential, built in passive fire protection, with performance requirements clearly identified for differing building types and uses as defined in Approved Document B of the Building Regulations, or as determined by a risk based approach to deliver fire safety within a building.

The performance is split into three distinct characteristics and (depending on the application) there may be a requirement for a combination of these:

Integrity – the ability for the fire resisting element to stop the spread of fire from one side to the other

Insulation – the ability to control the amount of heat transferred from the fire side to non fire side (necessary when protecting a means of escape past the area)

Smoke control – control of the volume of smoke that can escape through the separating element

The combination of performance requirements will determine what materials can be used and should only include materials that have been subject to primary testing.

How are fire rated internal glass doors made?

Depending on the manufacturer, each fire door is built differently. Testing of the fire door set must be undertaken in accordance with BS 476-22:1987 or BS EN 1634-1:2014 by an accredited test laboratory. Following successful testing it is possible to gain suitable classification certification and scope of manufacture.

When a product is certified, all fire doors produced within the certified scope should have a label affixed. This label will identify the manufacturer, date of manufacture as well as the fire rating and are typically located on the top edge of the door.

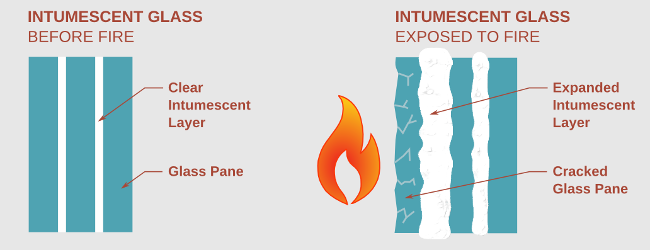

Where glass is used in a fire door it is important an appropriate fire rated glass is selected.

Standard float glass typically breaks at 120°C, while toughened glass can withstand temperatures of up to 260°C. Special fire rated glass is design to resist flames (often heat) as well as smoke and other toxic gases and is designed to withstand much higher temperatures, often up to 1000°C.

The main reason for this difference is due to its construction. Fire rated glass is made from several layers of toughened glass with intumescent interlayers. In the presence of a fire, the glass closest to the flames quickly heats up and will shatter into tiny pieces. This shattering effect 'activates' the intumescent interlayer – causing it to expand and effectively repelling the flames, heat and smoke.

Fitting fire doors can be complicated due to the regulations surrounding them. The Code of Practice for Fire Door Assemblies does not specify any certification requirements for fire doors. However, The Regulatory Reform (Fire Safety) Order (RRO) states that they should be installed by a competent person with the necessary training, experience, and qualifications. There will be further requirements in relation to this with the implementation of the forthcoming Building Safety Act.

A fire door, regardless of its rating, may not be able to withstand a fire for more than 5 minutes if it is not properly installed. Building regulations establish legal requirements and specifications for the installation of fire doors. For example, the gap between the fire door and the frame should be between 2 and 4mm.

Therefore, Internal fire doors must be installed by a suitably competent person. Clients should ensure that the person installing fire doors has received the necessary training and where possible, should be fitted under a Third Party Certification of competence e.g. FIRAS.

Using a qualified installer will give you peace of mind that the installation was done correctly and that the fire door will function properly in the event of a fire.

The importance of servicing your fire rated internal doors

Fire doors can become ineffective in the event of a fire due to regular use by building occupants and visitors. To ensure that fire doors have not deteriorated in condition and are fit for purpose, they should be inspected at least every six months

The RRO mandates that the building owner or responsible person subjects the fire doors to a suitable system of maintenance by a qualified technician and are maintained in an efficient state, in efficient working order and in good repair.

In addition, every building manager should regularly conduct these simple checks:

- The fire rated glass and glazing beads should be checked for signs of cracks and damage

- Mounting and assembly bolts are not missing or loose

- Open and close the fire rated door and inspect for any indications of damaged parts and make sure that the door can fully close

- Door frames must be firmly attached to the wall and free from damage

Share article

Have a question or need a quote?

We are here to help

Call us on +44 (0)1342 836630 to discuss your fire rated install requirements