As people look to build safer, more secure homes and businesses, fire rated glazing has become an increasingly attractive choice. Fire rated glazing is designed to be able to withstand and contain both fire and smoke, allowing more time for safe exit and keeping building contents safe from fire.

How do you know if glass is fire rated

Recent studies suggest that some non-compliant or fraudulent fire rated glazing materials may be on the market, which can have potentially hazardous implications for life safety.

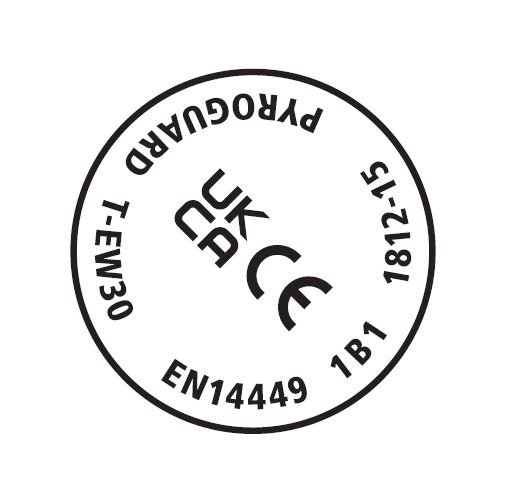

Therefore, each safety glass product must include an identification stamp to distinguish fire rated glass partitions from ordinary glass. This mark should be permanent and applied before the installation so that it can be seen even after it is put in place. While the stamp does not need to follow a particular pattern, it must contain three pieces of information:

- the name of the manufacturer or installer

- the identifier of the product standard the glass adheres to

- the impact safety classification according to EN12600

(Example fire safety stamp, Photo Credit: Pyroguard)

In essence, marking fire safety glass is meant to identify and trace the product, which is incredibly important for fire safety and general building safety. With the mark, it is easy to look at the glass and quickly understand who made it, which standard it adheres to, and how it was used.

Moreover, traceability is a key concept featured in Dame Judith Hackitt's 'Building a Safer Future' report and review. Knowing the origin of the building material, who is accountable for it, and its performance characteristics are essential to offer trust and peace of mind throughout the supply chain.

What is the British Standard for fire rated glazing?

According to the Building Regulations for England and Wales, Approved Document B outlines the areas where fire resistance products must be installed and at what level, but the regulations provide only a guideline and do not cover all situations. For example, depending on the height of the building, the depth of the basement, and the presence of sprinklers, fire resistance of up to 180 minutes may be required for buildings other than dwelling houses.

How thick should fire glass be?

Approved Document K of the Building Regulations focuses on protection against falling, collision, and impact. It states that certain parts of external and internal walls require impact glass, with doors and side panels requiring either class 2 (if the width is greater than 900mm) or class 3 (if the width is between 250mm and 900mm). In addition, any panes of a thickness greater than 6mm and an area less than 0.5m2, with a width of less than 250mm, must not be impact-rated glass.

To comply with UK regulations and the European CE marking requirement, all manufacturers of fire rated glass must adhere to BS EN 1363, the fire testing standard. Additionally, BS EN 13501-2 classifies glass according to its level of fire resistance (E, EW, and EI). Radiation control glass (EW) may be specified for specific applications, although it has yet to be acknowledged by UK Building Regulations, while integrity-only glass (E) is restricted in certain European countries as it is deemed less safe.

BS EN 12600 sets out the impact safety requirements for glass in buildings, with a pendulum impact test method used to classify glass products into three principal classes.

Each class is represented by a three-figure classification consisting of a digit, a letter, and another digit, such as 1B1, 2B2, or 3B3. The digit refers to the height from which a weight was dropped onto the glass and passed the impact test, with 1 representing 1200mm, 2 representing 450mm, and 3 representing 190mm. The letter represents how the glass behaves when it eventually breaks: A as annealed glass, B as laminated glass, or C as toughened glass. The final digit indicates the height at which the glass does not break, which will always be the same as the first digit for glasses A and B – for example, 1B1, 2B2 or 3B3.

Can anyone install fire rated glazing?

Installation of fire rated glazing must always be carried out by a competent person with relevant specialist knowledge, and the glazed system must be fitted into a frame with the appropriate test evidence.

Third party certification is a way to assure that a product is reliable and safe. Having third party certification for a fire rated glazing product and installation process has many benefits for customers, as it gives them peace of mind and a sense of assurance.

Third party certification includes rigorous testing and inspections to ensure that the product meets safety and quality standards. It also displays a commitment to customers that you are dedicated to the quality of your products.

Additionally, only approved glazing seals and bead types must be used for the glazed system. Finally, fire rated glass must only be part of an appropriately approved glazed system.

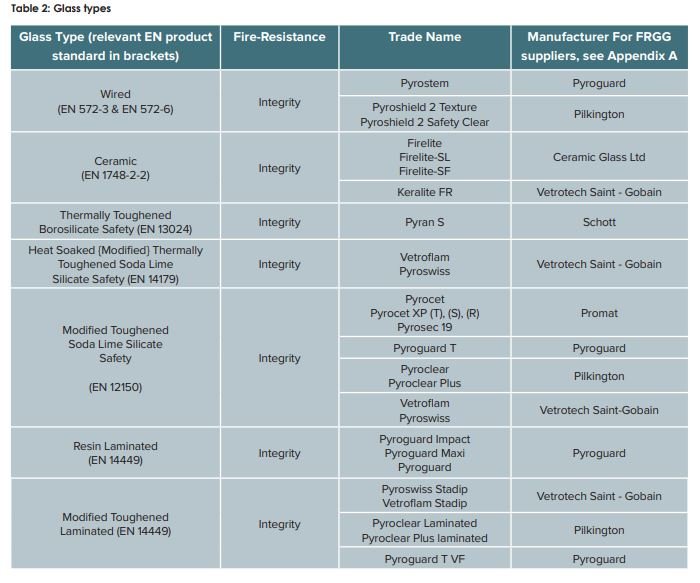

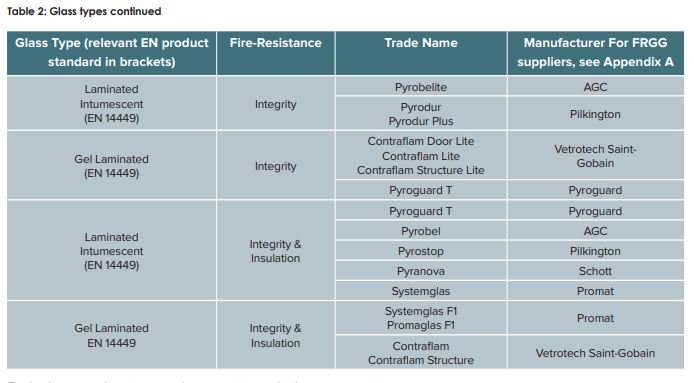

What are the different types of fire rated glazing?

The types of fire rated glazing available include wired, ceramic, heat-soaked modified thermally toughened soda lime silicate safety, resin laminated, modified toughened laminated, thermally toughened borosilicate safety, laminated intumescent, and gel laminated glass.

(Source: GGF – Fire resistant glazing guide 2018)

Insulating glass units are only considered fire rated if they comprise one of the fire rated glass types indicated in the above table and have undergone a fire performance test. It is important to take the following into account: the insulating glass unit must possess a fire test or assessment report based on test evidence, it must be CE marked or of a national equivalent under EN1279-5, it is sometimes necessary to ascertain the direction of use before installation, the components included in the insulating glass unit must be substantiated through testing or assessment, and the fire rated glazing system must apply to the integrated unit.

Always seek evidence from the manufacturer or supplier supporting the fire rated glazed system.

While most fire rated glazing systems are typically installed in a vertical manner, certain approvals do exist for inclined and horizontal orientations.

(Project: New Douglas Bennett House)

(Project: New Douglas Bennett House)

Some forms of glass decoration, such as sandblasting and screen printing, can be implemented without jeopardizing fire resisting performance, while others cannot - advice from the manufacturer or supplier must be obtained to ensure the treatment is suitable and the performance evidence is accessible.

Additionally, other performance characteristics, such as thermal insulation, safety and security, or privacy, can be coupled with fire rated glazing without compromising performance; though impact safety and manifestation, to decrease the probability of accidental walking into a fire rated glass partition must be given considerable consideration.

Specifying fire rated glass

When specifying a fire rated glass system, factors including fire-resistance performance criteria, integrity or insulation, internal or external application, safety and security necessities, acoustic or thermal performance, aesthetic preference, frame type and finish, and fixing details should all be taken into consideration.

Classifications

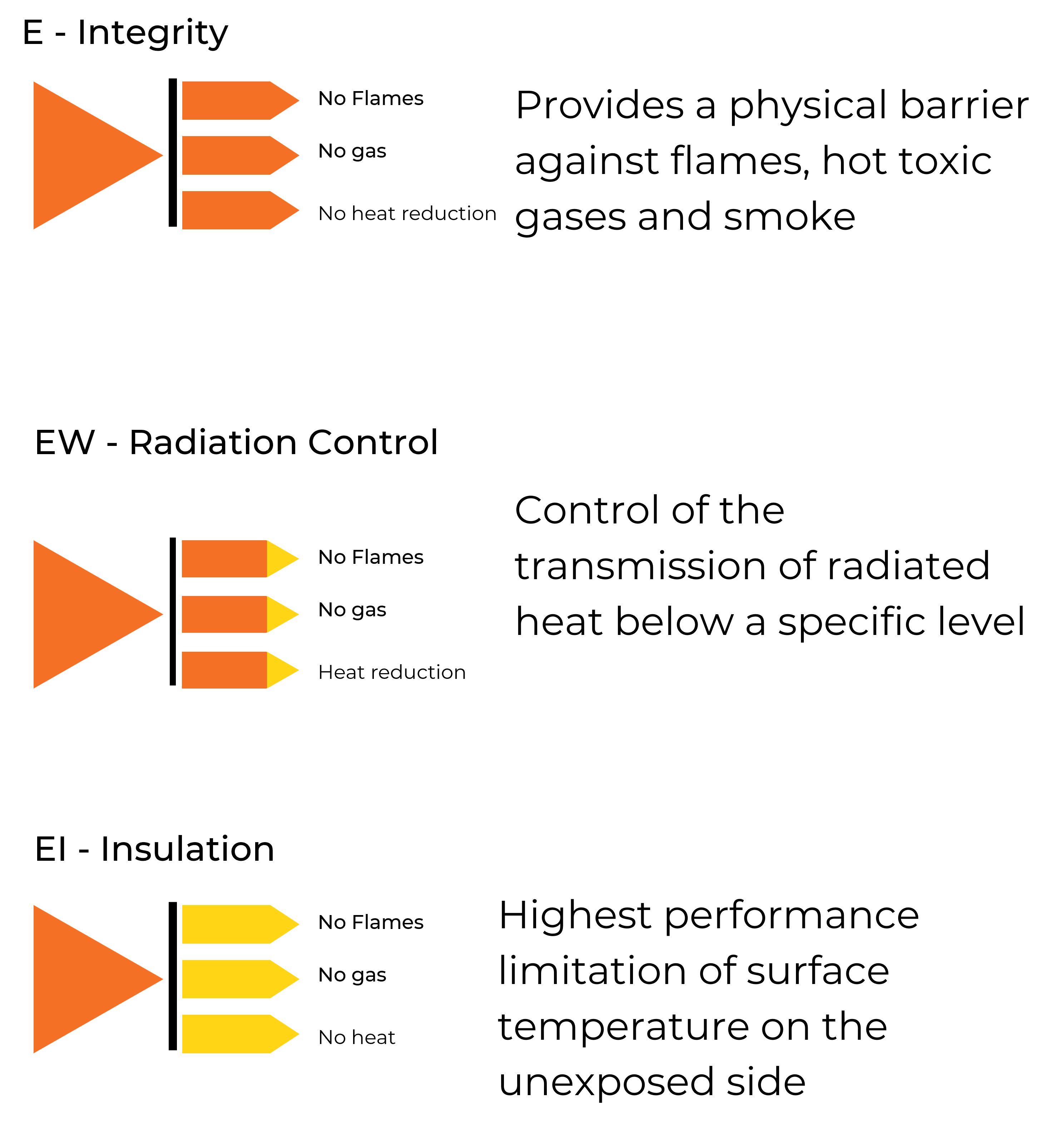

Integrity (E) - refers to the glass's capability of withstanding fire exposure on one side whilst stopping flames and hot air from seeping through to the unexposed side.

Radiation (W) - measuring the transmission of radiant heat at a distance from the face of the fire separating element (whilst extensively referenced in Europe, this is not commonly used in the UK. If insulation requirements are met, it is assumed that radiation requirements are also satisfied).

Insulation (I) - in addition to the traits of integrity, limits heat transfers due to conduction, convection, or radiation from the exposure to the unexposed face.

Approved Document B provides guidelines concerning integrity only, or integrity and insulation, and stipulates the relevant timeframes.

Energy performance

Fire rated glass is obtainable as single, double, and triple-glazed units.

Low emissivity or solar control layers help fulfil stipulated energy performance criteria, as in Part L of the Building Regulations.

Furthermore, fire rated glass can be applied to attain credits under the BREEAM rating system in numerous categories such as Energy (with the combination of fire glass and a low emissivity or solar control coated glass helping to provide the building with good thermal performance and energy conservation), and Health and Well-Being (glazed elements with a high light transmission permit a natural link to the exterior, thus promoting healthier working, learning and living environments, with fire glass normally providing impressive light transmission).

Acoustic properties

Multi-layered fire glass can offer a sound reduction in excess of 47 dB. This can help to meet Part E of the Building Regulations.

What are the advantages of fire rated glass?

One of the most surprising advantages of fire rated glass is its flexibility and choice. Fire safety glass doesn't necessarily mean unsightly fixtures around your office. Instead, it can come in various decorative patterns and applications, from frameless to coloured.

(Project: 33 Charterhouse)

(Project: 33 Charterhouse)

In conclusion, fire rated glazing is essential to building safety and preventing potential life loss in the event of a fire. It is a significant development in the fire safety building industry, allowing architects and designers to develop innovative solutions for fireproofing a building without sacrificing aesthetic appeal. Fire rated glazing can provide higher passive fire protection and may even reduce the need for further fireproofing measures. As always, consulting with a certified fire safety expert in evaluating fire resistance needs when designing a commercial building is essential. Through fire rated glazing, building occupants can feel secure that they are receiving necessary protection from the dangers of fire.

Frank Gehry once said, "Architecture should speak of its time and place but yearn for timelessness." With fire rated glazing, modern buildings can do both.

Share article

Have a question or need a quote?

We are here to help

Call us on +44 (0)1342 836630 to discuss your fire rated install requirements